Packaging

At Microbeam, we provide cutting-edge laser marking solutions tailored for the food and beverage industry. Laser marking technology is revolutionizing how packaging and products are labeled, offering superior quality, safety, and environmental sustainability.

The majority of packaging materials available today are composite multi-layer materials, and because each layer of material has unique properties during processing, laser requirements are comparatively high. The Maiman UV laser offers significant benefits for marking packaging.

Applications of Laser Marking

Expiration Dates and Batch Numbers

Ensure clear and permanent marking of critical information, such as expiry dates, lot numbers, and production dates, directly on bottles, cans, and flexible packaging materials.

Barcodes, QR Codes, and Traceability

Improve traceability and product recall capabilities with high-quality, machine-readable codes.

Logos and Branding

Enhance your brand’s presence with permanent, high-contrast logos and promotional messages directly on packaging.

Direct Product Marking

For certain food items like fruits, eggs, and bakery products, laser marking can add logos or traceability codes directly onto the product surface.

Laser Marking on Cold Drink Bottle

Laser Marking on Cold Drink Canes

Laser Marking on Water Bottle

Easy Tear Line Laser Marking

Laser Marking on Food Packets

Gems and Jewellery

At Microbeam, we specialize in providing advanced laser marking and cutting solutions that redefine precision and craftsmanship in the gems and jewellery industry. From intricate designs to flawless cuts, laser technology offers unmatched quality and efficiency for both natural and laboratory-grown diamonds.

Applications of Laser Marking & Cutting

Laser Marking

Engrave high-precision serial numbers, logos, and certification marks directly onto diamonds, gemstones, and jewellery pieces for authenticity and traceability.

Laser Cutting & Shaping

Achieve superior cutting quality and intricate shapes for diamonds and gemstones. Laser cutting ensures minimal material loss and high processing efficiency.

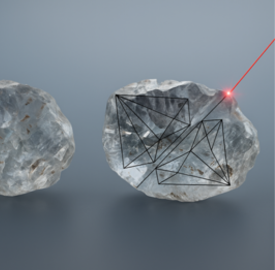

Planning and Coring

Facilitate accurate diamond planning, coring, and sawing with laser precision, ensuring optimal yield and minimal damage.

Key Benefits

Unmatched Precision

Laser systems deliver fine, detailed cuts and markings with micron-level accuracy.

Minimal Material Loss

Laser cutting ensures maximum utilization of valuable materials, reducing waste.

Permanent and High-Contrast Marks

Laser marking creates permanent, tamper-proof identifiers that meet industry standards.

Non-Contact and Safe

Laser processes avoid physical contact, reducing the risk of contamination or damage to delicate gemstones.

Enhanced Productivity

High-speed, automated laser systems streamline operations, reduce human error, and improve overall productivity.

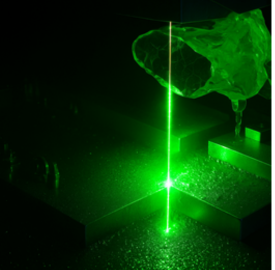

Green Laser Cutting Diamond

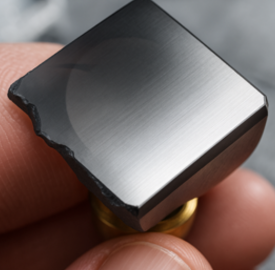

Diamond Slicing

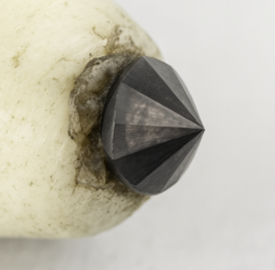

Diamond Facting

Diamond Planning

Diamond Coring

Semiconductors and Energy

At Microbeam, we provide state-of-the-art laser marking solutions tailored for the demanding environments of the semiconductor and energy sectors. Our precision laser marking systems deliver reliable, permanent, and contamination-free markings that support your manufacturing processes and ensure product traceability.

Applications of Laser Marking

Semiconductors & Microelectronics

Marking of semiconductor wafers, microchips, and electronic components with lot codes, serial numbers, barcodes, and data matrices for complete traceability.

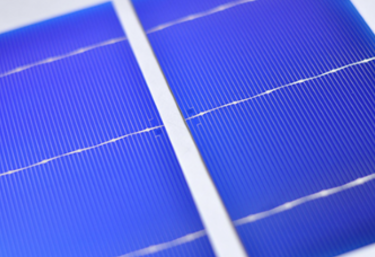

Solar & Photovoltaics

Marking solar cells, wafers, and panels with high-contrast and permanent identification codes without affecting electrical performance.

Battery & Energy Storage Systems

Engraving battery cases, modules, and energy storage components to ensure clear identification, quality control, and safety.

Key Benefits

High Precision and Clean Markings

Laser marking offers micron-level accuracy, producing clear, legible markings even on delicate or heat-sensitive materials like silicon wafers or thin-film photovoltaic materials.

Permanent and Durable

Laser-engraved codes and identifiers are permanent, tamper-proof, and resistant to environmental conditions such as heat, moisture, and chemicals.

Non-Contact and Safe

Laser marking is a non-contact process, which eliminates the risk of mechanical damage and contamination to sensitive semiconductor components.

Eco-Friendly and Cost-Effective

No inks, solvents, or consumables required – laser marking reduces environmental impact and long-term costs.

Compliance and Traceability

Ensures your products meet regulatory standards and enables robust traceability throughout the manufacturing process.

Solar Cell Slivers

Solar Cell Film P2 And P3 Layer Scribing

Diamond Facting

SiC Single Wafer Dicing

Semiconductor Wafer 2

Pharmaceutical and Medical

At Microbeam, we offer advanced laser marking solutions tailored for the pharmaceutical and medicine packaging industry. Laser marking ensures secure, permanent, and precise identification critical for patient safety and regulatory compliance.

Applications of Laser Marking

Serialization and Traceability Codes

Mark permanent, high-contrast barcodes, QR codes, and data matrix codes on medicine blister packs, cartons, and labels to meet strict serialization requirements.

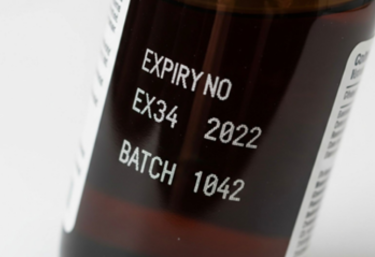

Expiry Dates, Batch Numbers, and Dosage Info

Accurately mark essential information directly onto packaging materials, ensuring reliable identification throughout the supply chain.

Branding and Anti-Counterfeiting

Mark logos and security features onto pharmaceutical packaging to protect brand integrity and prevent counterfeiting.

Key Benefits

High Precision and Readability

Laser marking delivers clear, legible marks even on small or delicate packaging materials, enhancing product safety and traceability.

Permanent and Tamper-Proof

Laser marks are resistant to smudging or fading, ensuring long-lasting legibility and compliance with regulatory standards.

Non-Contact and Clean Process

Laser marking avoids physical contact, reducing the risk of contamination and maintaining the integrity of sensitive medicines.

Eco-Friendly and Cost-Efficient

No inks, solvents, or consumables—laser marking offers a sustainable and cost-effective solution compared to traditional printing methods.

Compliance with Global Standards

Ensure your packaging meets strict industry regulations, such as those set by the FDA, EU FMD, and other global authorities.

Laser Marking Syringe

Laser Marking on Medicine Packets

Laser Marking on Cough Syrup

Automotive and Aerospace

At Microbeam, we deliver precision laser marking solutions engineered to meet the demanding needs of the automotive and aerospace industries. Our advanced laser systems ensure permanent, legible, and tamper-proof markings on a wide range of components, contributing to safety, traceability, and compliance.

Applications of Laser Marking

Automotive Applications

Component Identification

Mark critical components like engine parts, pistons, gears, and brake systems with serial numbers, barcodes, and data matrices for traceability and quality control.

Safety & Compliance

Mark airbag housings, seatbelt components, and electronic modules to meet stringent safety standards.

Branding

Laser-engrave logos and branding on vehicle parts for brand integrity and anti-counterfeiting.

Aerospace Applications

Part Traceability

Mark turbine blades, airframe structures, and fasteners with permanent identifiers for maintenance and safety.

Regulatory Compliance

Meet strict aerospace standards for identification and documentation.

Material Versatility

Laser marking works on aerospace-grade materials like titanium, aluminum, carbon composites, and more.

Key Benefits

High Precision & Clarity

Laser marking produces sharp, readable codes even on challenging or curved surfaces.

Durable & Permanent

Laser-engraved marks withstand harsh environmental conditions, such as heat, chemicals, and vibrations, ensuring long-term reliability.

Non-Contact & Clean Process

Laser marking is a non-contact technology, reducing the risk of part damage or contamination during processing.

Eco-Friendly & Cost-Effective

No need for inks, solvents, or consumables — laser marking is both sustainable and cost-efficient.

Enhanced Traceability & Quality Control

Permanent laser markings ensure complete product traceability and help meet rigorous industry standards for safety and quality.

Automotive Ceramic Parts Marking

Aluminum Oxide Blackout